Biogas is a renewable energy source that is created by the process of decomposition of organic materials. It can be used as a renewable energy source for heating, electricity generation and transportation. Biogas can be generated from various sources such as agricultural waste, food waste and manure from livestock. It can also be generated from other organic materials such as plant biomass, paper and wood pulp.

What is needed for Biogas production?

1. Biogas Digester

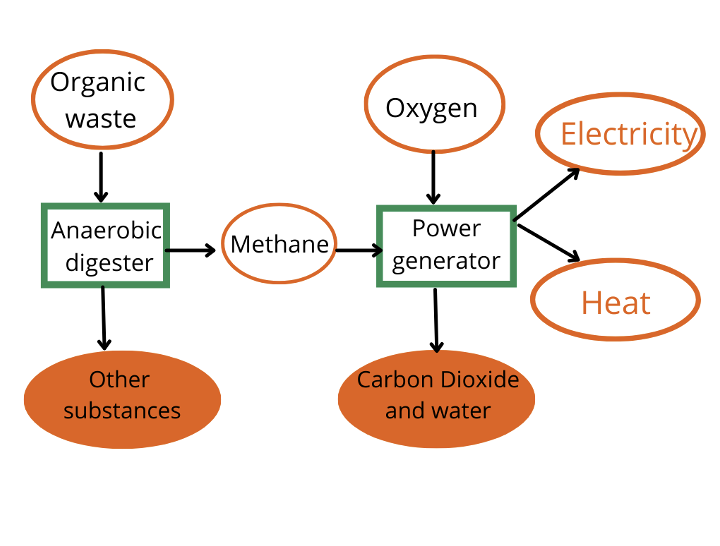

Anaerobic biogas digester installation converts organic waste into methane gas. This type of biogas technology requires anaerobic bacteria to break down the organic matter in an oxygen-free environment. The end product is methane gas, which can be used as electricity for homes or fuel for stoves to cook food. The biogas digester also contains carbon dioxide that forms after anaerobic decomposition of organic matter.

2. Biogas generator

This is a system of motors that aid in converting the biogas (mainly consists of methane which is highly flammable) into electricity. The biogas generator will require warm temperature since the biogas production takes place in a warm environment similar to that of an animal or human gut. Biological activity inside the generator produces heat, however during cold weather additional warmth must be provided.

3. Organic waste

Organic or biowaste incudes; plant biomass, kitchen refuse and cow dung (manure). The biomass is mixed with water in the biodigester where it is broken down under temperatures between 70 -105°C. In the case of plant bio mass, the bio matter is crushed into small pieces before being added to the biodigester. Cow dung or manure on the other hand contains carbon which is the major chemical element. For anaerobic bacteria to digest this carbon so as to release biogas, nitrogen has to be present. Anaerobic bacteria rely on nitrogen to derive energy from carbon making it crucial to have the right ratio of nitrogen to carbon. On the other hand, a higher ratio of nitrogen from high concentration of ammonium can be toxic.

This diagram is a process flow chart for the production of biogas from organic waste.

Bio Gas Installation and How Much Is Produced

The following are factors to consider when installing a biogas digester system;

1. Biogas digester design

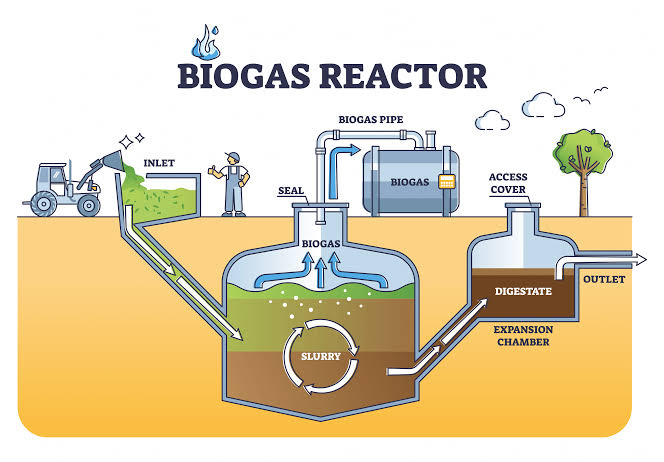

A biogas digester is practically a tank that contains the biowaste and a provision to collect produced gases. An efficient biogas digester design contains an inlet and an outlet to pipe off the gas as well as dry off the effluent. The bio gas digester needs a provision to stir the bio matter as it grinds them for it to work. There are many models of a biogas digester as they are built differently, the amount of organic waste you collect in a day however determines the size of the Biogas digester.

2. Biogas digester capacity and output

Relatively, a 1000 litre home biogas digester ought to produce 1m3 of biogas in a day when filled with organic waste. The biogas digester produces biogas 1-3 weeks after using the bio waste. When using cow dung one can multiply the number of cows by 0.5 to estimate the amount of gas in cubic meters per day. An effective biogas burner consumes 0.5m3 of gas every hour.

3. Biogas digester safety

Practice biogas safety by ensuring there are no open flames within six meters of a biogas digester tank. All biogas should be emptied before any repairs or inspections of the bio gas digester is carried out.

Summary

Biogas consumption has increased over the decades as a source of fuel as well as electricity. In today’s article we try to answer, what is biogas and how is it produced?